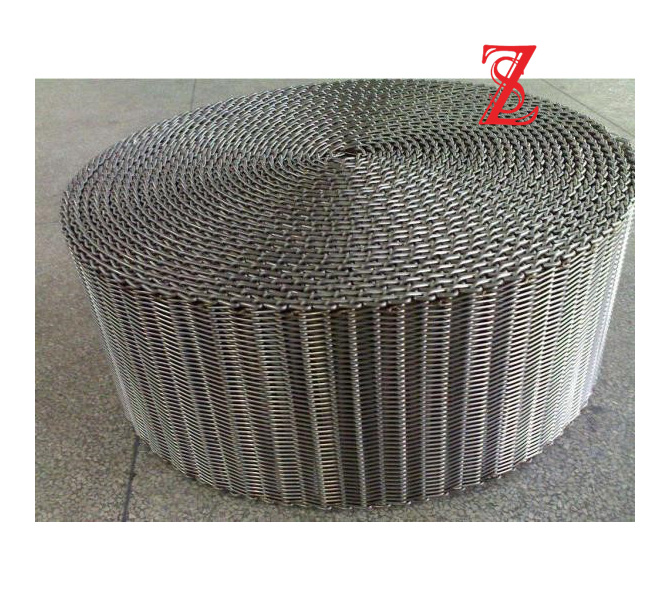

Steel Pipe Winding Mesh

Pipe winding mesh is used as reinforcement for steel pipe which will be coated with concrete and then submersed in water or earth. The wire mesh acts as a holding and reinforcement agent during the process of concrete coating thus gives additional strength to the concrete coated pipe. The wire mesh helps in holding the concrete intact even after drying preventing the steel pipe from corrosion by not exposing the steel pipe to water or moisture for many years after installation. This helps in the longer life of the pipe laid to transfer water/oil as per end user requirements. With precise mesh opening and heavy coating we shall produce the excellent quality wire mesh suitable for pipe coating applications.

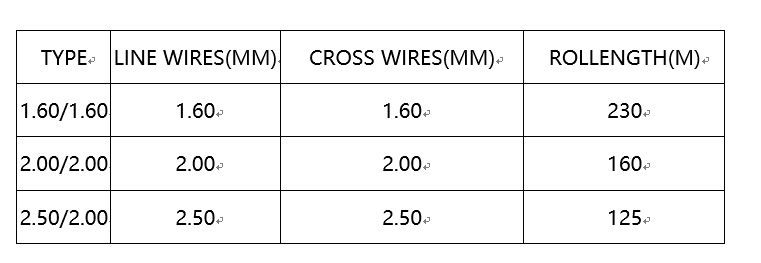

Wire DIA: 1.6/1.6mm; 2.0/2.0mm; 2.5/2.0mm +/-0.05mm

Mesh size: line wire: 25.4+/-2mm

Cross wire: 67+/-5mm or 92.4+/-5mm

Core diameter of the roll:800mm

Roll width: 190.5 to 266.7mm

Roll length: 230; 160; 125m

Packing:

Rolls strapped into bundles of 5 or 6 rolls

Standard types

The exceptional continuity and uniformity of Pipe Coating Mesh enhances even more the ability of the concrete coating withstand impact.

The high degree of flexibility in the longitudinal direction of the Pipe is important for spreading and minimizing cracks during the laying of the pipeline.

A coating reinforced with QWP Pipe Coating Mesh has uniform compressive strength.

The use of hot-dip galvanized wire extends the lifetime of the reinforcement.

steel pipe winding mesh to be used as reinforcement for the concrete applied in the manufacture of negative buoyancy pipe needed for laying pipe in marshes or in water. This mesh can also be used as reinforcement for concrete applied to pipe as a bendable or nonbendable mechanical protective coating when laying pipe in a harsh environment. The steel from which the wire is produced shall be made by any commercially accepted steelmaking process and the zinc coating shall either be of a Class 1 or a regular coating. Welded meshes shall be obtained by welding a series of parallel longitudinal wires to transverse wires to form rectangular openings. Stripping and tensile tests shall be performed to determine the coating weight and tensile compliance of the specimen.